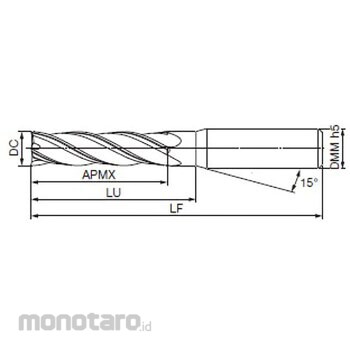

Sumitomo Electric Hard Metal GSX MILL 4-flute end mill sharp corner GSX40000S-4D type

#Grup produk P114335593

Sebelum PPN:

Rp799.900 - Rp17.999.900

Ketersediaan:

Periksa Metode Pembayaran dan Estimasi pengiriman

Spesifikasi

| Bit size | Sharp corner |

|---|---|

| Coating | GSX coat |

| Grade | ACF20 |

| Helix Angle (°) | 30 |

| Number of Tips | 4 |

| ROHS Directive (Corresponding to 10 Substances) | Correspondence |

| Shank Diameter Tolerance | h5 |

Pilih jenis produk yang diinginkan

| Nomor SKU | Model Number | Masa Persiapan Barang | Harga | Jumlah |

|---|---|---|---|---|

| Loading... | ||||

Informasi Produk

Description

Improved reliability in wet machining by using fine-grained carbide base material with high transverse rupture strength and excellent thermal shock resistance.

Adoption of GSX coat with improved wear resistance and heat resistance improves reliability and service life.

Large rake angle and unique groove shape improve sharpness and chip evacuation.

S type (sharp corner) that emphasizes sharpness. The S type is ideal for removing corner residue.

Side machining: Finish ◎, Groove machining: Finish ○ (*Please use with a smaller depth of cut), Groove finish machining: Finish ◎

In order to perform stable machining, please use rigid and highly accurate machines and holders.

*For dry processing, please use air blow.

*When processing stainless steel, heat-resistant alloys, and titanium alloys, please process wet.

*Chattering is likely to occur in the early stages of machining, but chatter may be eliminated after machining approximately 2m.

Adoption of GSX coat with improved wear resistance and heat resistance improves reliability and service life.

Large rake angle and unique groove shape improve sharpness and chip evacuation.

S type (sharp corner) that emphasizes sharpness. The S type is ideal for removing corner residue.

Side machining: Finish ◎, Groove machining: Finish ○ (*Please use with a smaller depth of cut), Groove finish machining: Finish ◎

In order to perform stable machining, please use rigid and highly accurate machines and holders.

*For dry processing, please use air blow.

*When processing stainless steel, heat-resistant alloys, and titanium alloys, please process wet.

*Chattering is likely to occur in the early stages of machining, but chatter may be eliminated after machining approximately 2m.

Ulasan Produk

Tidak ada ulasan