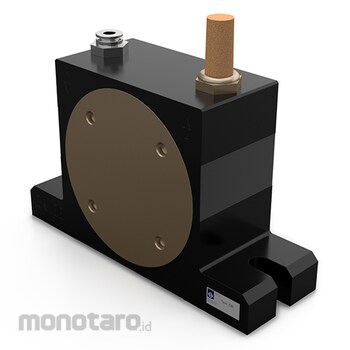

OLI PNEUMATIC OR - ROLLER VIBRATOR

#Grup produk P110161370

Sebelum PPN:

Rp2.499.900 - Rp5.299.900

Ketersediaan:

Periksa Metode Pembayaran dan Estimasi pengiriman

Spesifikasi

| Material | Aluminium body and brass cover |

|---|---|

| ATEX | II 2D c Tx II 2G c Tx |

| Technology | Roller vibration - high frequency and centrifugal force |

| Working Temperature (°C) | From -20 to 200 (from -4 °F to 392 °F) |

| Air Supply Quality | Class 5.4.4. |

| Duty cycle | Discontinuous |

| Maximum Noise Level (dBA) | <90 |

| Pneumatic Circuit | Filter + flow control valve + lubrification + 3/2 ways valve N.C. |

| Powder | Hygroscopic |

| Problem Solving | Bridge and rat-holing - friction reduction - separation |

| Working Pressure (Bar) | From 2 to 6 (from 29 psi to 87 psi) |

Pilih jenis produk yang diinginkan

| Nomor SKU | Model Number | Masa Persiapan Barang | Harga | Jumlah |

|---|---|---|---|---|

| Loading... | ||||

Informasi Produk

Description

In the OR series, high frequency vibration is generated by a roller that describes an epicycloidal movement inside two housings made of hardened and ground steel. The OR series is characterized by high speed, great centrifugal force (up to 783 kg) and low air consumption.

Advantages

- High centrifugal force

- Easy to install

- Suitable for high temperatures

Certifications

The OR series pneumatic vibrators are designed and built according to the following standards: UNI EN 13463-1 – EN 13463-5 – ISO 14121 – UNI EN 1127-1 and in compliance with directives 2014/34 / UE

They are certified ATEX II 2D c Tx – II 2G c Tx to be used in potentially explosive environments.

NOTE: Dimensions with coarse degree of accuracy related to UNI 22768/1

Advantages

- High centrifugal force

- Easy to install

- Suitable for high temperatures

Certifications

The OR series pneumatic vibrators are designed and built according to the following standards: UNI EN 13463-1 – EN 13463-5 – ISO 14121 – UNI EN 1127-1 and in compliance with directives 2014/34 / UE

They are certified ATEX II 2D c Tx – II 2G c Tx to be used in potentially explosive environments.

NOTE: Dimensions with coarse degree of accuracy related to UNI 22768/1

Feature

The body of the OR series products is made of anodized aluminum while the covers are made of brass.Lubricated air supply is required, with operating pressures from 2 to 6 bar (29 ~ 87 PSI). Noise at full speed does not exceed 90 dB (A).

The OR roller vibrator series consists of 4 sizes and able to operate in environments with temperatures up to + 200 ° C (+ 392 ° F).

Use

OR rotational roller vibrators are used on silos, hoppers, pipes and chutes, as well as in compacting concrete.The installation does not require drilling the walls of the application, for this reason they are particularly suitable for integration on existing systems and machinery.

Ulasan Produk

Tidak ada ulasan