Pilih jenis produk yang diinginkan

| Nomor SKU | Model Number | Masa Persiapan Barang | Harga | Jumlah |

|---|---|---|---|---|

| Loading... | ||||

Informasi Produk

Description

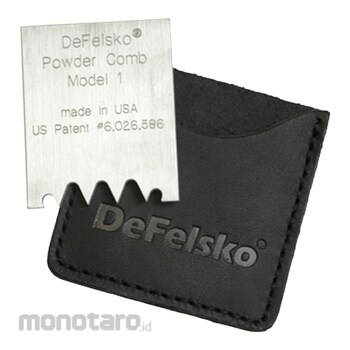

DeFelsko Powder Comb

Check Powder Thickness Before Curing to Ensure Correct Cured Film Thickness

Check Powder thickness with Powder Comb before curing to help ensure correctly cured film thickness the first time through the line. Avoid stripping and re-coating which can cause problems with adhesion and coating integrity.

- Works on a variety of part sizes, shapes and substrates such as metal, plastic, wood, glass, and more

- Broad stand-offs on both sides of teeth help keep gage perpendicular to surface when measuring

- Precision gage; manufactured to a tolerance ±5 microns or ±0.0002 inch

- Protective leather pouch included with each gage

Check Powder Thickness Before Curing to Ensure Correct Cured Film Thickness

Check Powder thickness with Powder Comb before curing to help ensure correctly cured film thickness the first time through the line. Avoid stripping and re-coating which can cause problems with adhesion and coating integrity.

- Works on a variety of part sizes, shapes and substrates such as metal, plastic, wood, glass, and more

- Broad stand-offs on both sides of teeth help keep gage perpendicular to surface when measuring

- Precision gage; manufactured to a tolerance ±5 microns or ±0.0002 inch

- Protective leather pouch included with each gage

Feature

Versatility • Ideal for set-up and quality control

• Works on a variety of part sizes, shapes and substrates such as metal, plastic, wood, glass, and more

• Easy to carry; convenient shirt pocket size

• Available in mils (inch) or microns (metric)

Quality

• Broad stand-offs on both sides of teeth help keep gage perpendicular to surface when measuring

• Rugged aluminum construction for long gage life and static control

• Precision gage; manufactured to a tolerance of ± 0.0002 inch

• Protective leather pouch included with each gage

Simple Operation

1 - Push the Powder Comb perpendicularly into the dry powder so that the two stand-offs (end tabs) on both sides of the teeth rest firmly on the substrate.

2 - Drag the Powder Comb along the surface of the coated part for at least 1/2 inch.

3 - Remove the Powder Comb from the surface and examine the marks left in the powder. The powder thickness is between the highest numbered tooth which made a mark and has powder clinging to it, and the next highest tooth which left no mark and has no powder clinging to it.

Ulasan Produk

Tidak ada ulasan