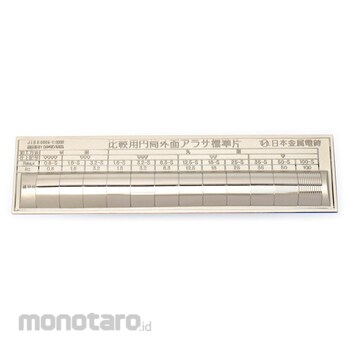

Japan Metal Electroforming Cylindrical Outer Surface Roughness Standard

#Grup produk P107202075

Spesifikasi

| Griding 1 (S/Rz) | 0.8 |

|---|---|

| Griding 2 (S/Rz) | 1.6 |

| Griding 3 (S/Rz) | 3.2 |

| Rounding 1 (S/Rz) | 1.6 |

| Rounding 2 (S/Rz) | 3.2 |

| Rounding 3 (S/Rz) | 6.3 |

| Rounding 4 (S/Rz) | 12.5 |

| Rounding 5 (S/Rz) | 18 |

| Rounding 6 (S/Rz) | 25 |

| Rounding 7 (S/Rz) | 35 |

| Rounding 8 (S/Rz) | 50 |

| Rounding 9 (S/Rz) | 100 |

Pilih jenis produk yang diinginkan

| Nomor SKU | Model Number | Masa Persiapan Barang | Harga | Jumlah |

|---|---|---|---|---|

| Loading... | ||||

Informasi Produk

Description

There are two ways to measure roughness by comparing the roughness standard piece and the actual product: visual and tactile. Except for very rough surfaces, the tactile method is the correct answer.

In terms of tactile sensation, rubbing with the tip of the fingernail seems to be more sensitive than touching with the pad of the finger. Alternatively, light rubbing with the tip of a pencil may be performed for comparison. However, when the glossiness of the surface becomes a problem, of course, it must be done visually. The degree of roughness that can be visually and tactilely discerned is usually around 0.8S.

In terms of tactile sensation, rubbing with the tip of the fingernail seems to be more sensitive than touching with the pad of the finger. Alternatively, light rubbing with the tip of a pencil may be performed for comparison. However, when the glossiness of the surface becomes a problem, of course, it must be done visually. The degree of roughness that can be visually and tactilely discerned is usually around 0.8S.

Ulasan Produk

Tidak ada ulasan